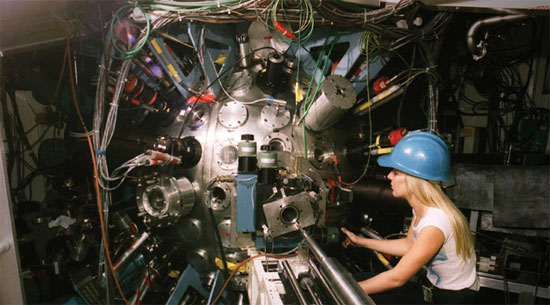

Figure 1: Peregrine is skilled at process development

Nuclear Metals of Concord, Massachusetts requested that Peregrine assist in developing processes in parallel with their casting development of beryllium aluminum alloys. Primarily the interest of Nuclear Metals was for Peregrine to develop and confirm that the processes involved with attaching mechanical fasteners/ threaded inserts, adhesive bonding, and the ability to press and shrink fit pins into their advanced cast alloy would be successful. Along the way, Peregrine developed techniques in order to be able to successfully perform all those functions to a level commensurate with placing the finished hardware on airframes for the U.S military. Peregrine was asked to focus on three areas. They were as follows:

- The adhesive bonding of beryllium aluminum cast alloy to beryllium aluminum cast alloy.

- Develop procedures to be able to press pins into this cast material with an interference fit.

- Develop techniques in order to use a standard helicoil insert in the material without causing stress concentrations or stress fractures.

Attached to this description is each of the final reports on the procedures and information utilized to successfully develop these processes. You will note in the attached reports that we were able to successfully develop an adhesive system that could provide shear strengths to a value in excess of 2500 psi. Peregrine was able to verify that the full strength of bolts within a –55°C to a +125ºC range was achievable by using helicoil inserts within the beryllium aluminum cast material. In addition, Peregrine was able to develop techniques in order to press and shrink fit pins into the beryllium aluminum cast material resulting with no evidence of parent metal failures.

All these processes were critical in allowing the use of beryllium aluminum cast products into advanced avionic systems including FLIR systems.

Peregrine assisted Nuclear Metals in developing these processes along with typical machining parameters in order to provide successful products into the aerospace and other high tech industries. We typically develop processes and procedures for advanced materials so that they can be utilized in high performance applications.