Peregrine undertakes design to performance or build to print contracts. Where the latter is defined by drawings and specifications, the former is typically defined through a “Statement of Work” with a morphological chart, which is usually a joint effort with our customer. Once the statement of work is created, Peregrine then sets upon the path to design, manufacture and test the product.

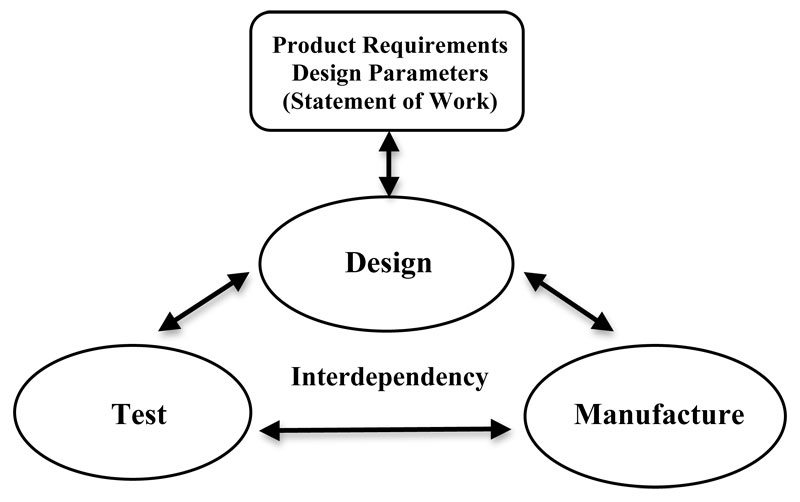

There is an interdependency between the functions of design, manufacture and test. Typically, designers rely upon standards and established software to formulate designs. Manufacturers understand that the materials and processes used to fabricate a design may never be perfect and that the design standards and software have built in safety factors to allow for imperfections. Testing’s role is to verify that the “as built” hardware passes the design’s minimum requirements. Where this is a macro description, challenges and difficulties arise as the Product Requirements/Design Parameters start approaching the limitations of what the design, manufacture and test loop can provide. Peregrine’s experience and heritage with taking many projects through the design, manufacture and test loop has given us insight in how to make a successful product. Our Quality Assurance Program is run to ISO9001/AS9100. A partial list of our capabilities is presented below.

|

|

|

| The Hypothesis | The Principles | The Journey |

Design and Analysis

- Computer Aided Engineering/Modeling

- Simulation/Analysis

- Linear Static Stress Analysis (tension, compression, torsion and bending)

- Vibration (dynamic) Analysis

- Nonlinear and Buckling Analysis

- Thermal Analysis (conduction, convection and radiation)

- Fatigue Analysis o CFD Fluid Flow Analysis

- FMEA, Failure Mode Effect Analysis

- Fracture Toughness Analysis

- Design Optimization

- Computer Aided Manufacturing

- Computer Aided Inspection

Manufacturing Processes

- Conventional and CNC Machining through 5-Axis

- EDMing; plunge and wire

- Grinding; cylindrical and surface

- Gun Drilling

- Metallurgical Joining; soldering and brazing (ATM and VAC)

- Liquid Interface Diffusion Bonding, Diffusion Bonding, GTAW, MIG, TIG and EB Welding

- Epoxy Bonding

- Finishing: surface prep, chem film, primers, thermal coatings, dielectric coatings

- Thermal Processing: heat treat, stress relief, hot form, and super plastic forming

- Others; per customer requirements

Type of Testing

- Thermal Vac

- Tensile testing: room temperature and elevated temperature

- Thermal Cycling

- Dye Penetrant (both special level and standard level)

- Ultrasonic Testing

- Thermography

- Radiographic

- Neutron

- Vibration

- Other (product specific)

The above is a partial list; please contact us directly to discuss your specific needs.

PEREGRINE

Phone 925-461-6800

Fax 925-461-6804

1051 Serpentine Lane, Suite 100

Pleasanton, CA 94566